Werk24 Understands Tolerances from Technical Drawings

Imagine building a complex machine, only to find that the components don't fit together. For example, some are too large to match the required space. Who is guilty of that? Don't overthink because the answer is: Tolerance.

Tolerances might sound like technical jargon but have no fear; we're here to simplify the concept and demonstrate how Werk24 AI revolutionizes the precision game.

Understanding Tolerances

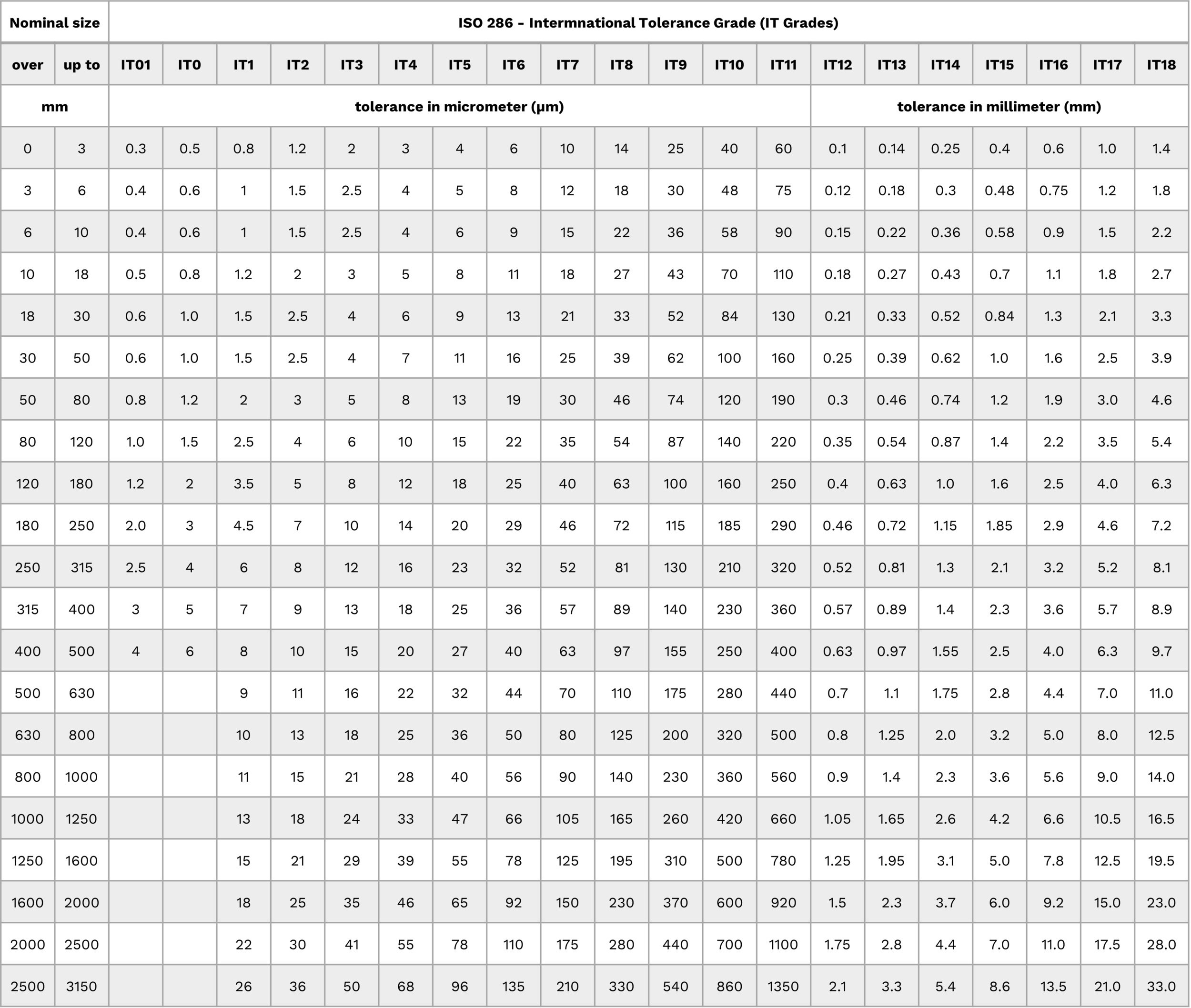

Technical drawings' Tolerances specify the allowable variation in a product's dimensions, ensuring its precise functioning while remaining economically viable to manufacture. So, ignoring tolerances can result in numerous difficulties during the assembly process and substantial cost increases. Tolerances are categorized by an international code system in 18 categories to handle linear tolerances within single numbers. This system is defined as ISO 286 or IT Grades.

IT Grades

The IT Grades are clearly organized from IT01 to IT18 in the table below. And this categorization only defines the Tolerances, Deviations, and Fits for standard measurements up to 3150 mm, but IT grades can also be extrapolated. At every fifth stage from IT6 to IT18, the standard tolerances are multiplied by a factor of 10. This method extrapolates values for IT grades that are not explicitly enumerated, making it an efficient engineering tool.

Fits and Tolerances

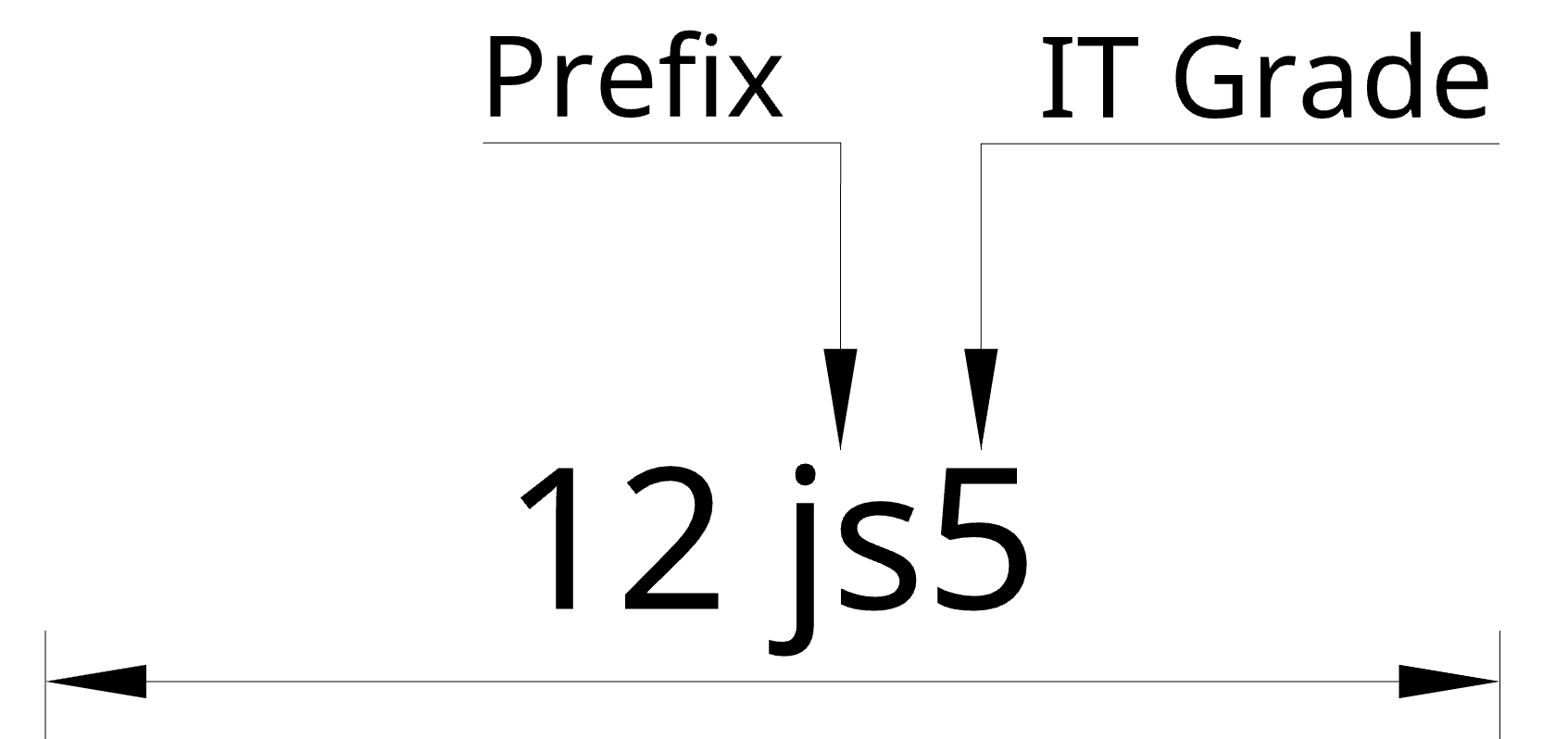

In Fits, you've probably encountered IT Grades before; they might be familiar to you. Fits define the correlation between two mating parts by considering the size disparity before assembly. To specify these Fits, IT grades with standardized prefixes define the tolerance limits. So, Fits consist of two key elements: (I) the location denoted by a standardized prefix, typically represented by 1-2 characters, and (ii) the width, described by the IT grade. An illustrative example is provided below:

In this example, instead of using 'IT,' the prefix 'js' indicates a symmetrical distribution; hence a dimension 12 js5 is equivalent to 12±0.004 (where 12 IT7 is 0.008). This allows for greater control over the Fits, ensuring a perfect match between mating components. You can learn more about IT Grades from our previous blog article.

How Does Werk24 AI Support You?

Tolerances may seem like a minor detail on technical drawings. Yet, they play a crucial role in ensuring the flawless assembly of complex machinery and precision engineering. There are various types of tolerances, such as General Tolerances, Deviation Tolerances, Limit Tolerances, and Single Limit Tolerances, each conveying the same information but presented differently. You can explore our Knowledge Base to learn about these diverse tolerance types. Leveraging the power of Werk24 AI, understanding these distinct representations of tolerances in technical drawings becomes effortless, and it extracts precise information into a single output using IT Grades. So, the next time you encounter tolerances in your technical drawings, remember that Werk24 AI has your back to streamline your manufacturing processes!